Think back to your middle school math class – do you remember learning to measure three dimensional objects and ultimately calculate the volume of said objects?

Measuring a box seems simple enough! LxWXH. Right?

However, for custom packaging these dimensions are crucial to your product’s safety!

Box dimensions are a critical part of any package because the dimensions of a box have an impact on what materials are needed, the cost of production as well as shipping and warehousing costs.

Think of it this way; minimal room for movement in the box means minimal room for damage and reduction of your overall costs.

Accurately measuring a box for a custom packaging project is quite a bit more complex than it may seem at first glance.

Here we lay out the top considerations and a step by step guide for measuring the dimensions of your box.

The Three Dimensions of a Box

The first step to creating the ideal packaging is understanding how to measure a box’s dimensions accurately.

While this may seem like basic math, measuring your dimensions with care requires some consideration.

So, what dimensions are needed exactly?

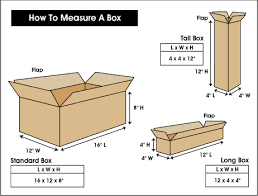

The three main dimensions by which boxes are measured include length, width, and depth.

To get started, look at the top opening of the box to measure the following dimensions;

- Length: The longest side when looking at the top of the box.

- Width: The shorter side when looking at the top of the box.

- Depth (Height): The side perpendicular to the length and width.

In the case of a tall or upward-facing box, the depth will be the largest dimension while the length and width will be smaller.

While square boxes in theory should have equal sides, this is less likely to be true in packaging.

So, make sure you measure each dimension accurately to ensure your packaging is up to par for your products!

For long boxes, the depth and width will be much smaller in comparison to the length.

The type of box you choose will be dependent on your product’s shape and size.

However, the measurements required for production, regardless of the type of box, will still be dependent on the length, width and depth.

The Importance of Internal Dimensions

The industry standard for box dimensions is based on the internal measurements.

The distinction between the internal and external dimensions is important for obtaining packaging that fits your products perfectly.

The Internal dimensions are much more accurate for both the manufacturer and your product!

Most manufacturers are very specific about the size of dimensions both internal and external and rightly so.

After all, no one wants their products to get damaged because of incorrect measurements.

While it may seem more natural and easier to measure the external dimensions for a box, the internal dimensions is what really matters for your custom packaging project.

This ensures your product can actually fit inside of the box and you can tailor the measurements to make sure your product is secure.

Leaving minimal room for movement inside of the box will guarantee your products’ safety during shipping and handling and allow your business to provide high quality products every time.

The Issue of External Dimensions

If a box is measured by its external dimensions, it could prove to be problematic as external dimensions don’t factor in the thickness of a box, which could result in packaging that doesn’t quite fit.

This could feasibly damage particular products that need the packaging to be a tight fit.

This is why calculating the measurement of a box via its internal dimensions removes any shred of doubt.

This is especially important in the case of corrugated boxes.

Corrugated boxes feature a fluted texture weaved between two paperboards, making the material thick and adding a couple of millimeters to every measurement you take from the outer lining of the box.

This is why the internal dimensions will provide you more accurate measurements, in turn making it easier to determine the box size you need to package your products.

Calculating the Volume of a box

The volume will help you determine your shipping, warehousing and distribution processes more easily.

Furthermore, it will help you determine how well your product will fit into your desired packaging.

The volume plays a crucial role in material and cost optimization as well as structural engineering of your packaging!

So, be sure not to skip over this step!

Now that you have your basic dimensions it’s very easy to determine the volume of your box.

Simply multiply the three dimensions to get a volume measurement.

Length x Width x Depth = Volume

Note: This measurement will be in cm or inches cubed.

Now that you have a better understanding of how to measure the dimensions of your box more accurately, you can apply these dimensions to any packaging project you require