When looking to design a custom box, our designers prefer to have as much information as possible to create the right package. With that said, here are their hopes and dreams, and why this information is mission critical.

ALL THE PRODUCT

If your pack requires it holds 20 “bottles” our design team would prefer to have all 20. Having one and extrapolating the size may produce human error. By having all the product, it will allow them to figure out if partitions or dividers are needed, what configuration is best, as well as the size and shape of the carton itself. This will also allow them to design for the most cost effective manufacturing process in our plant.

PROTOTYPE OR FINAL APPROVED PRODUCT

Is the sample our design team working with a prototype or the final design? This may sound trivial but an 1/8″ can effect the overall size of each piece of the package. If it a prototype and the final product is a different size, it is as if we are starting over on ALL pieces of the package. Also, are there additional pieces to the package? Power cords, lids, tubes, chargers? All these will effect the overall configuration design.

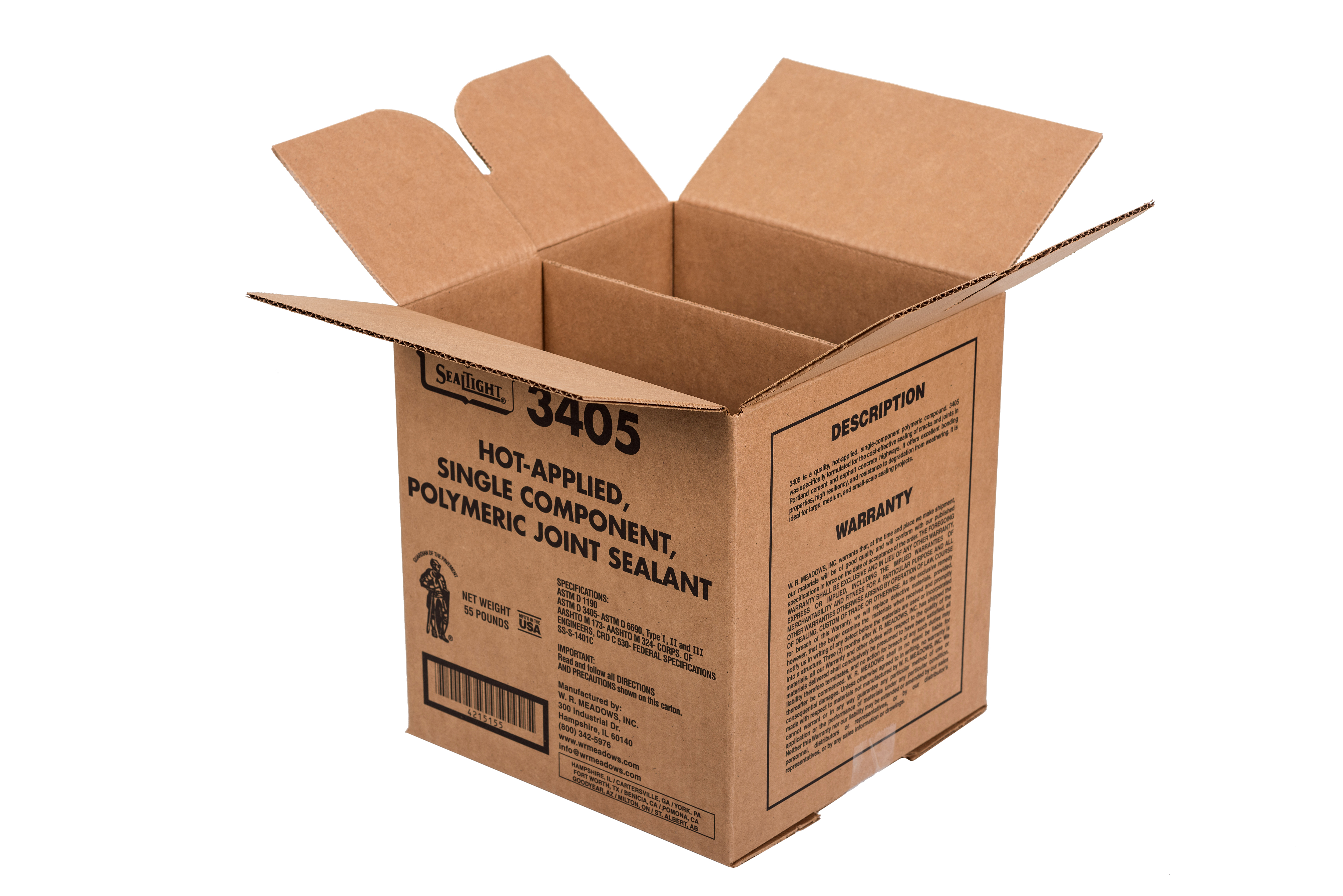

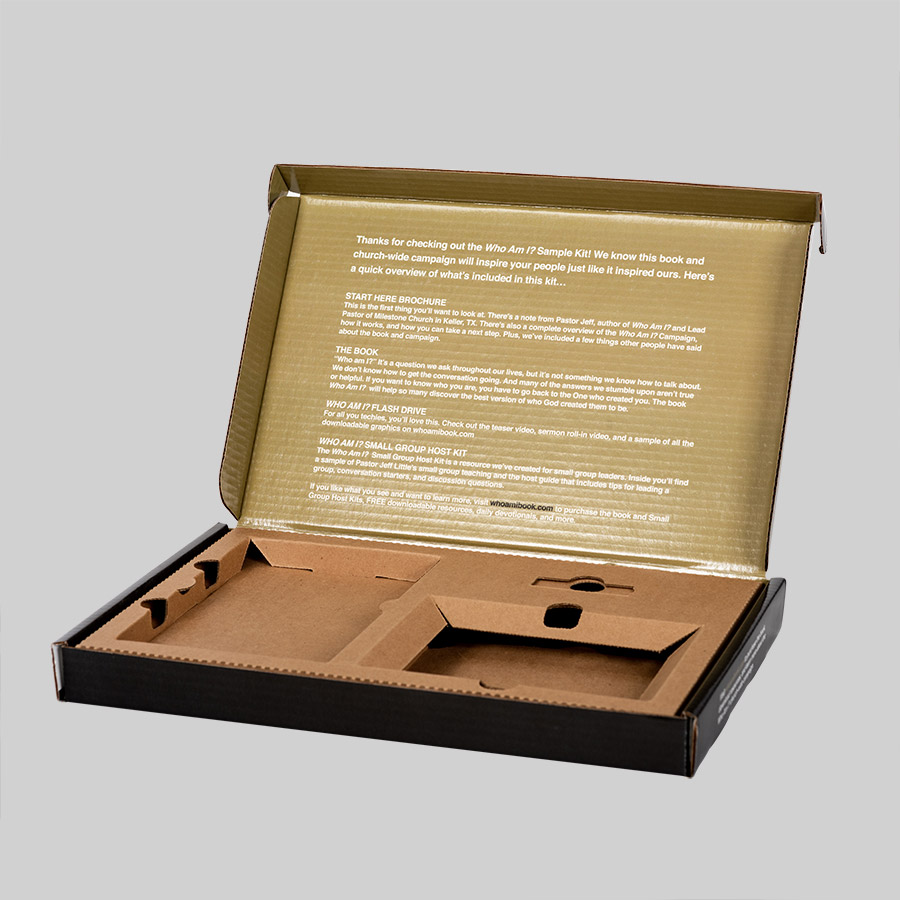

TYPE OF PACKAGE EXPECTATION

Will this pack be for industrial shipping or is it a high end piece? Will the carton be printed? Number of colors? Will it be litho labled? Do you have artwork? All these factors can play into how the carton is designed as well as produced. Do you want custom inserts? Will you be using packing peanuts or bubble wrap? Do you want us to design a custom foam insert to protect the product during transit?

HOW WILL THE PACK BE SHIPPED?

Will your product go out on pallets in a semi-trailer? Or will they go via FED-EX or UPS? If you will ship it on a semi-trailer we will work to design a carton that fits well on a 48 x 40 pallet to maximize the trailer space. If it will go via UPS or FED-EX we will design a pack that can will hold up during transit.

PACK OUT PROCESS

If at all possible, we would love to come out and see your facility and how you expect to pack out this product. In doing so we might adjust the design to best fit your assembly line or even suggest process improvement. Our design team can also see how it will be stored as well as shipped out.

THANKS

Creating a custom carton takes a lot of time and creativity. Our goal is to always provide you the best pack we can. In providing us the information above ensures we can create the best possible solution for you. Please reach out to us and let us work on your next project! info@pack-design.com