Cutting dies are an extremely important part of producing your custom packaging or display. So, let’s take a look at how they work and how they are made.

Corrugated cutting dies are made up of a wood substrate and metal cutting and creasing rule. Cutting dies are what transform a blank sheet of corrugated material into the finished packaging you need to send out or display your product. Incorporating your custom graphics and art on your packaging is the subject of a future blog post (so stayed tuned).

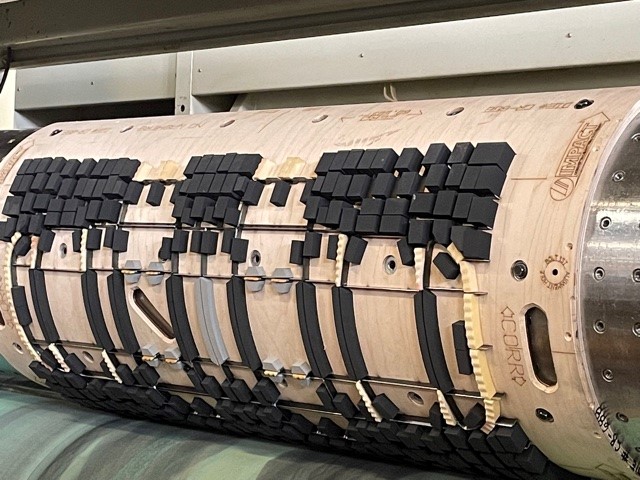

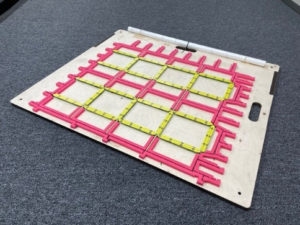

There are two types of cutting dies, rotary and flat. Here at Packaging Design Corporation we have machines which utilize both types of cutting dies. Rotary dies are semi-circular and are built for running on machines which incorporate a rotating cylinder. The cylinder rolls over corrugated material which is being fed into the machine, cutting it into the finished shape. Flat dies, on the other hand, are built to go on a machine which cuts corrugated using the up and down motion of a platen hitting a flat anvil. Both types of cutting dies and machines have their own advantages and are geared towards specific types of packaging.

While cutting dies may look “old school” or low tech, they are actually made to exacting standards and built to last through many production cycles. Here is how they are made: When a customer’s packaging design is approved, a CAD (Computer Aided Design) file is sent to a diemaker where it is used to create

I hope this has been a helpful glimpse into what corrugated cutting dies are, how they are made, what they do, and why they are important to your packaging project. Here at Packaging Design we have a lot of experience with cutting dies and all facets of corrugated manufacturing. We look forward to partnering with you to create your custom packaging or retail display.