Back in November we introduced you to the concept of how your projects are estimated and planned. We covered the materials in the first segment, and to refresh your memory, or if you missed it, you can catch it here.

For part two in our series, we are going to explain how packaging construction affects the overall cost and outcome of your project for die-cut items.

Packaging construction

The number of die cuts in a run (or order) and the size and complexity of the die-cut dictates the size and capacity of the cutting die.

Custom cutting dies

All die-cuts require a custom cutting die, which you pay for as part of your tooling, this is a one-time charge. The cost of the cutting die is typically proportionate to the size and complexity of the item. The more board required to make it, the more material, and hence the more it will cost.

Multiple-out cutting dies

One factor in the speed of production is how many items can be produced out of each sheet or cutting die. A 2-up, 3-up, or 4-up cutting die is a higher investment because it requires more board/ material and a larger cutting die. But at higher quantities, these multiple-out cutting dies pay off because the factory can produce your order much faster.

Manufacturers will always run as many items “up” as is cost effective for the production run. They will consider your order quantity, your forecasted quantity of that item throughout the year, the size of your box, and whether it is printed or plain to find the sweet spot of cost, die type, and efficiency.

Gang running packaging

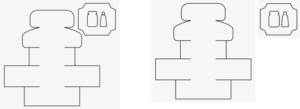

A gang run describes grouping multiple items on single sheet, to be cut and printed at the same time. This is an excellent cost saving strategy if you have multiple corrugated items that you order in the same ratios or for the same project.

For example, if you have a box with a dedicated insert that goes out with every shipment, you could gang both items on one cutting die so that you’re paying for one production run instead of two. Keep in mind that since ganged items are produced in the same run, they will all be made from the same material, using the same print process.

When a box can be ganged with its insert, the items can be produced in one run instead of two.

We hope we’ve shed some light for you on the complexity and components that go into producing your work. It is crucial that you partner with a company that understands that complexity and knows how to make the most of your materials to get you the best possible outcome for your investment. With over FIFTY years in the packaging industry, Packaging Design stands at the ready to advise you and help you create eye catching packages, give your customers a great experience, and help you maximize your investment.